A PHP Error was encountered

Severity: Notice

Message: Undefined offset: 0

Filename: views/product_view.php

Line Number: 66

A PHP Error was encountered

Severity: Notice

Message: Trying to get property 'st_product_name' of non-object

Filename: views/product_view.php

Line Number: 66

A PHP Error was encountered

Severity: Notice

Message: Undefined offset: 0

Filename: views/product_view.php

Line Number: 66

A PHP Error was encountered

Severity: Notice

Message: Trying to get property 'st_image' of non-object

Filename: views/product_view.php

Line Number: 66

A PHP Error was encountered

Severity: Notice

Message: Undefined offset: 0

Filename: views/product_view.php

Line Number: 72

A PHP Error was encountered

Severity: Notice

Message: Trying to get property 'st_product_name' of non-object

Filename: views/product_view.php

Line Number: 72

A PHP Error was encountered

Severity: Notice

Message: Undefined offset: 0

Filename: views/product_view.php

Line Number: 72

A PHP Error was encountered

Severity: Notice

Message: Trying to get property 'st_product_name' of non-object

Filename: views/product_view.php

Line Number: 72

-

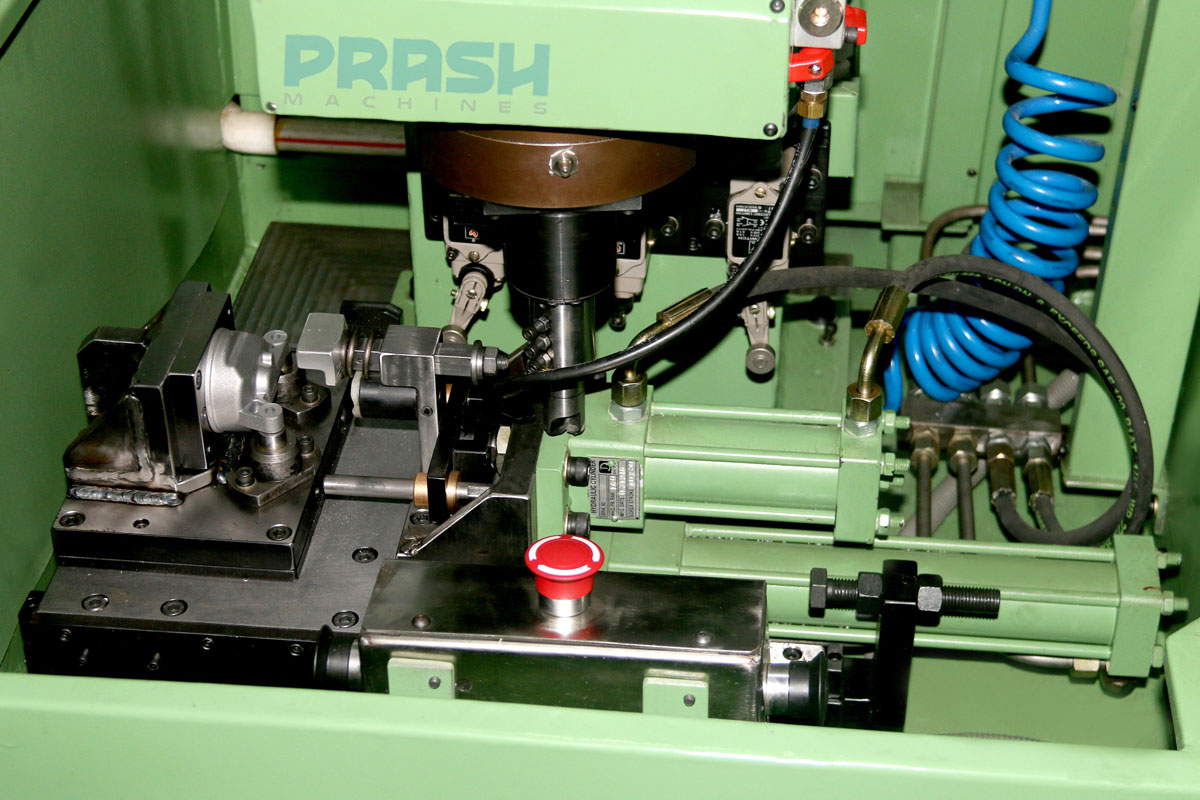

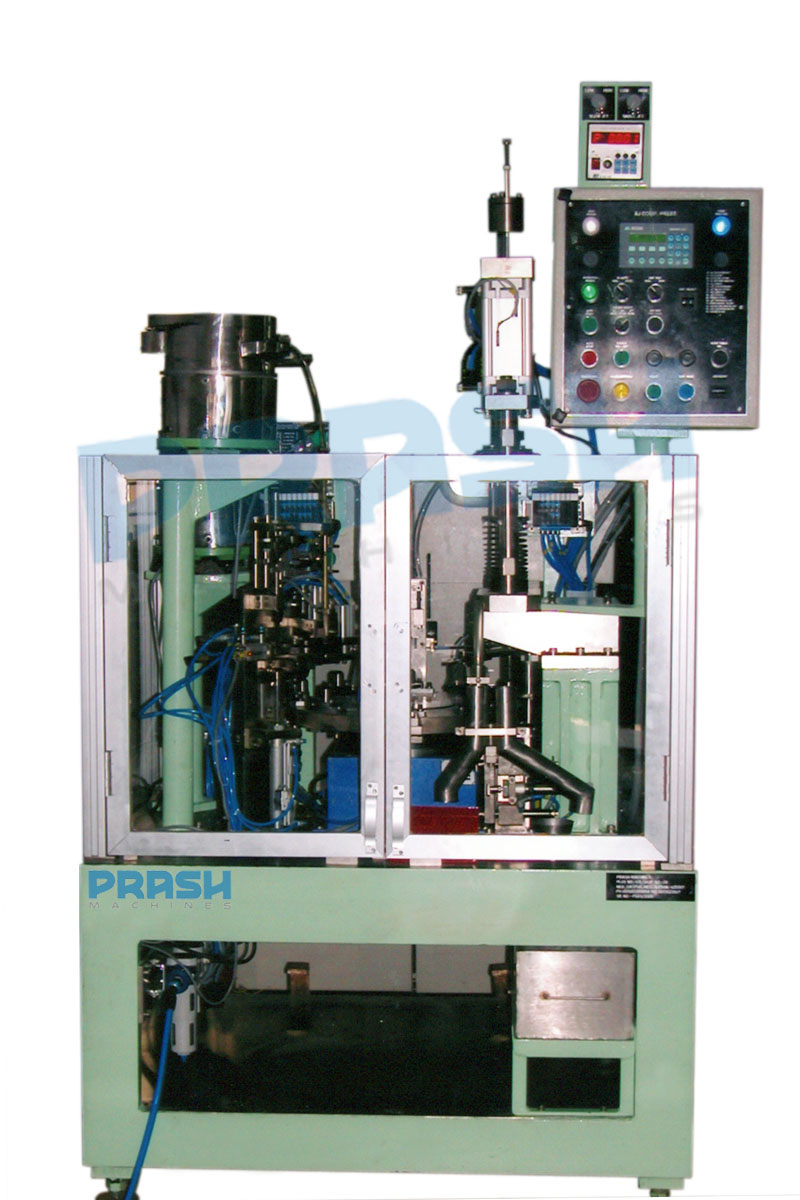

Pneumatic actuation

-

Adjustable Rapid advance & feed stroke

-

Pneumatic/Hydraulic actuation

-

Easily accessiDifferent speeds by changing pulley ratioble Limit Switch actuators & controls Easily

-

Adjustable Rapid advance & feed stroke

-

Different speeds by changing pulley ratio

-

Inbuilt easy belt tensioning arrangement

-

Auto Coolant Arrangement

-

Slim design

-

Precisely made for small to heavy duty drillingg

-

Rigid Table Structure

-

Inbuilt easy belt tensioning arrangement

-

Pneumatic/Hydraulic actuation

-

Adjustable Rapid advance & feed stroke

-

Different speeds by changing pulley ratio

-

Inbuilt easy belt tensioning arrangement

-

Cartridge type Spindle design

-

Highly precise and robust Spindle

-

Non drifting Spindle

-

High thrust powerful drilling

-

Most Versatile and flexible

-

Peck option suitable for long drilling

-

Cartridge type Spindle design

-

Highly precise and robust Spindle

-

Compact design

-

Economical

-

Available in Pneumatic & Hydraulic

-

High pneumatic rapid

-

Adjustable Rapid Forward-Feed-Rapid Return

-

Precisely made for small to heavy duty drillingg

-

Rigid Table Structure

-

Drilling Head Up & Down Arrangement

-

Easily accessible Limit Switch actuators & controls

-

Precisely made for small to heavy duty drillingg

-

Rigid cast iron housing

-

Precision spindle tapers & tool holding collets

-

High thrust powerful drilling

-

Different speeds by changing pulley ratio

-

Slim design

-

Precisely made for small to heavy duty drillingg

-

Drilling Head Up & Down Arrangement

-

High-rigid, high precision Spindles

-

Rigid cast iron housing

-

Precision spindle tapers & tool holding collets

-

High thrust powerful drilling

-

Slim design

-

Precisely made for small to heavy duty drillingg

-

High -rigid, high precision Spindles

-

Easily accessible Limit Switch actuators & controls

-

Rigid cast iron housing

-

Precision spindle tapers & tool holding collets

-

High thrust powerful drilling

-

Precise and rigid LM Guide Slide

-

Adjustable Rapid Forward-Feed-Rapid Return

-

Non drifting Spindle

-

Precise and rigid LM Guide Slide

-

Adjustable Rapid Forward-Feed-Rapid Return

-

High Productivity

-

High thrust powerful drilling

-

Precise and rigid LM Guide Slide

-

Adjustable Rapid Forward-Feed-Rapid Return

-

High Productivity

-

Most Versatile and flexible

-

Peck option suitable for long drilling

-

Precise and rigid LM Guide Slide

-

Adjustable Rapid Forward-Feed-Rapid Return

-

Fix or AdjustableCenter distances

-

Drill Length variation compensating Spindles

-

Silent running by Harden & Ground Gears

-

Radial Float & Length Compensation Spindles for Tapping

-

Customized Drilling capacity &Matrix

-

Suitable to be mounted on any drilling machine

-

Precise Tapping with guaranteed gauge qualification

-

Easy quick changeable Harden & Ground Lead Screw

-

Radial Float & Length Compensation Spindles

-

Clutch Collet Adaptor for Tap safety

-

Compact design

-

Economical

-

Available in Pneumatic, Hydraulic& Servo Feed

-

High pneumatic rapid

-

Adjustable Rapid Forward-Feed-Rapid Return

-

Compact design

-

Economical

-

Available in Pneumatic & Hydraulic

-

High pneumatic rapid

-

Adjustable Rapid Forward-Feed-Rapid Return

-

Cartridge type highly precise and robust spindle

-

High thrust powerful drilling

-

Precise and rigid LM Guide Slide

-

Robust Column

-

Adjustable Rapid Forward-Feed-Rapid Retur

-

Box Type Robust Column

-

Most Versatile and flexible

-

Peck option suitable for long drilling

-

Precise and rigid LM Guide Slide

-

Adjustable Rapid Forward-Feed-Rapid Return

-

Box Type Robust Column

-

High Productivity

-

High thrust powerful drilling

-

Precise and rigid LM Guide Slide

-

Adjustable Rapid Forward-Feed-Rapid Return

-

Box Type Robust Column

-

High Productivity

-

Most Versatile and flexible

-

Peck option suitable for long drilling

-

Precise and rigid LM Guide Slide

-

Adjustable Rapid Forward-Feed-Rapid Return

-

Box Type Robust Column

-

Doubled output

-

Compact design

-

Economical

-

Available in Pneumatic & Hydraulic

-

High pneumatic rapid

-

Adjustable Rapid Forward-Feed-Rapid Return

-

Precise Tapping with guaranteed gauge qualification

-

Easy quick changeable Harden & Ground Lead Screw

-

Radial Float & Length Compensation Spindles

-

Clutch Collet Adaptor for Tap safety

-

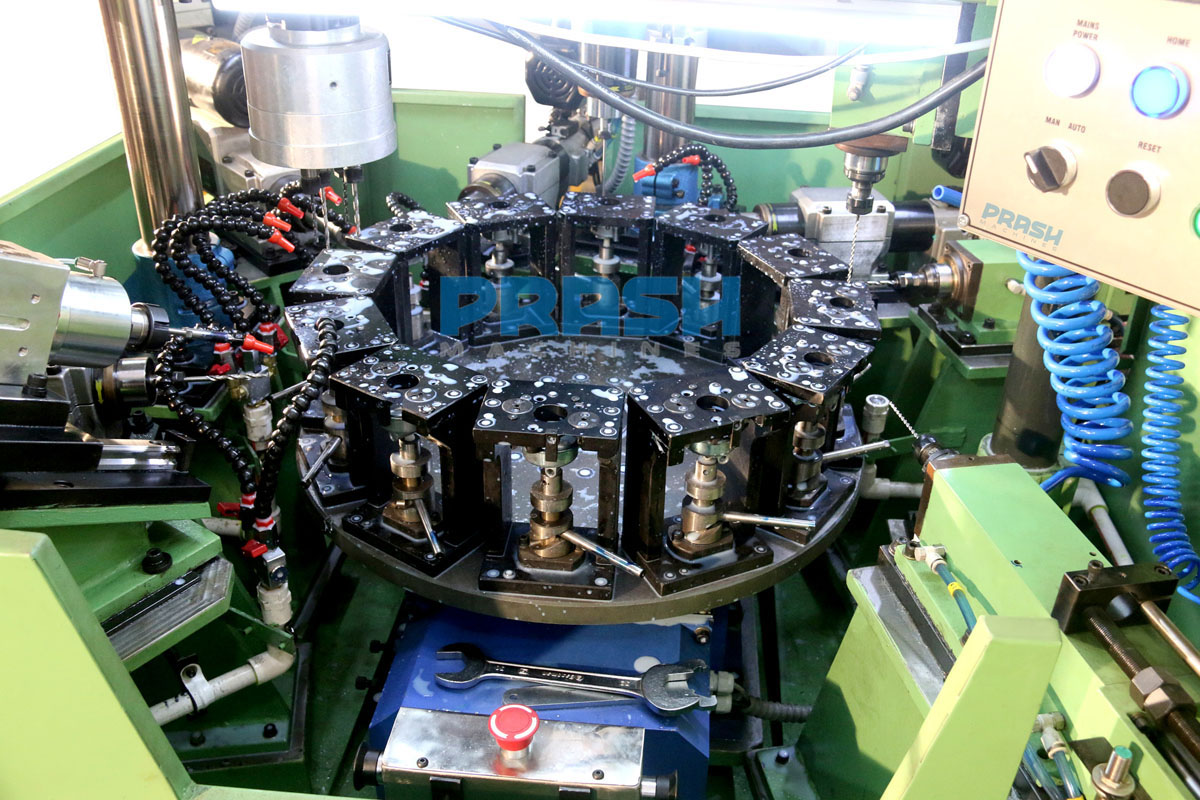

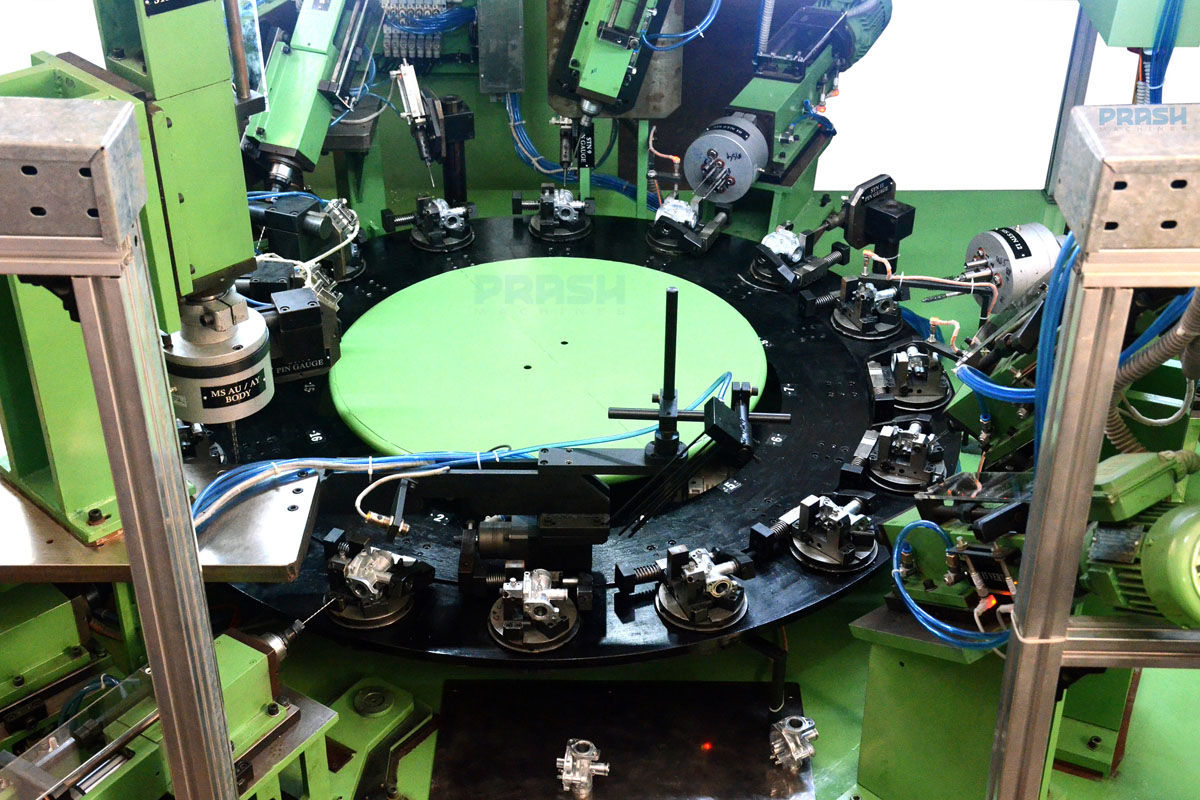

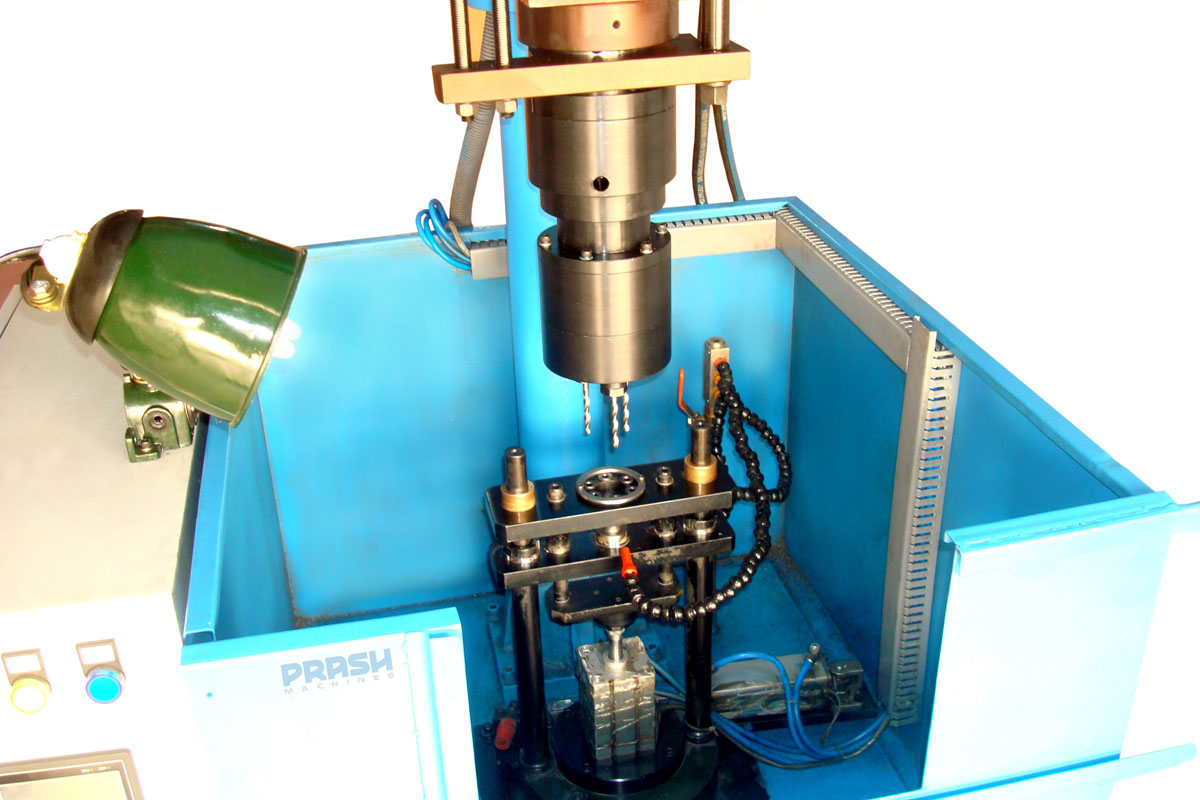

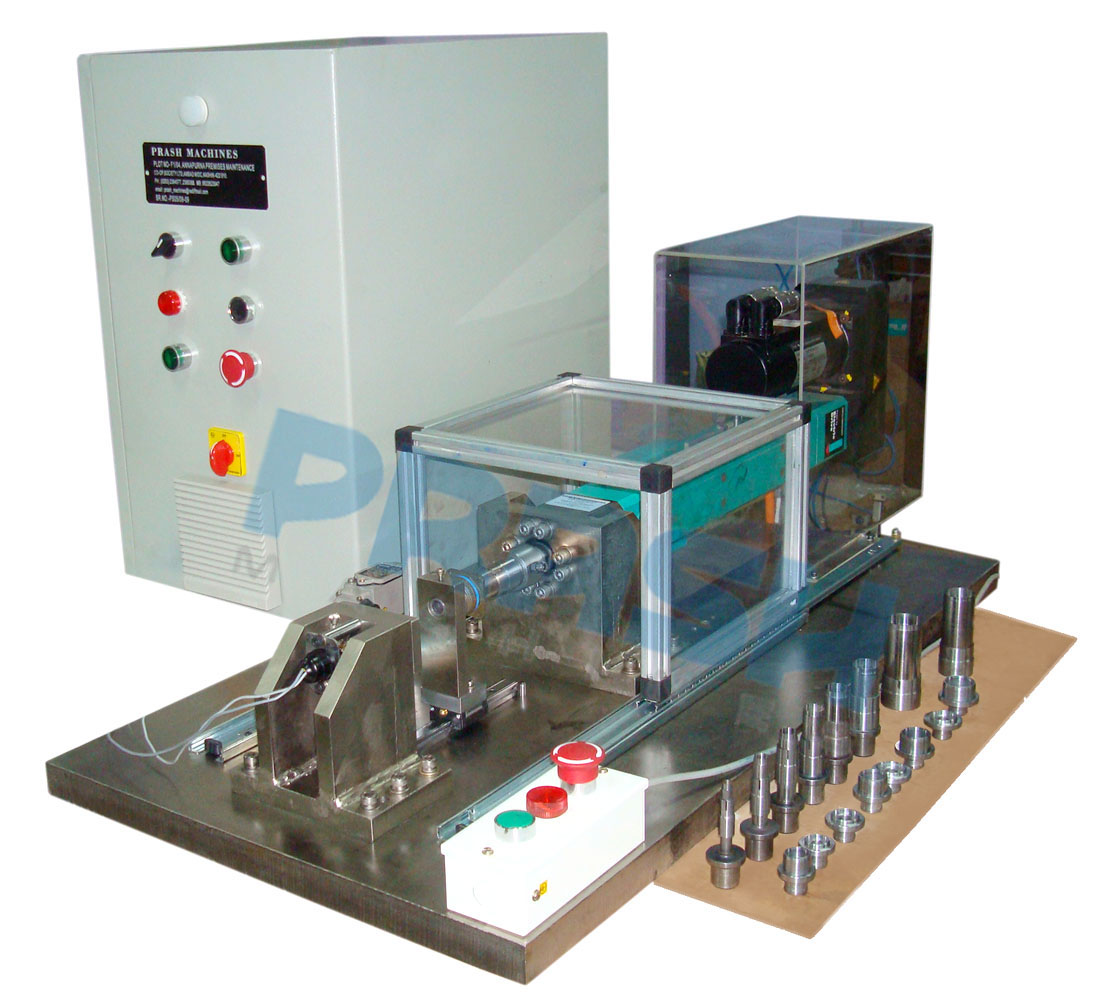

Multiple operation Drilling/Tapping/Reaming

-

Rotary Indexer with Hirth Coupling

-

Cam Type Fixture

-

Cam/Spring/Toggle Auto/manual part clamping

-

Manual/Auto Part Loading/Unloading

-

Bottom Bearing support for Index Top Plate

-

Auto recirculating coolant

-

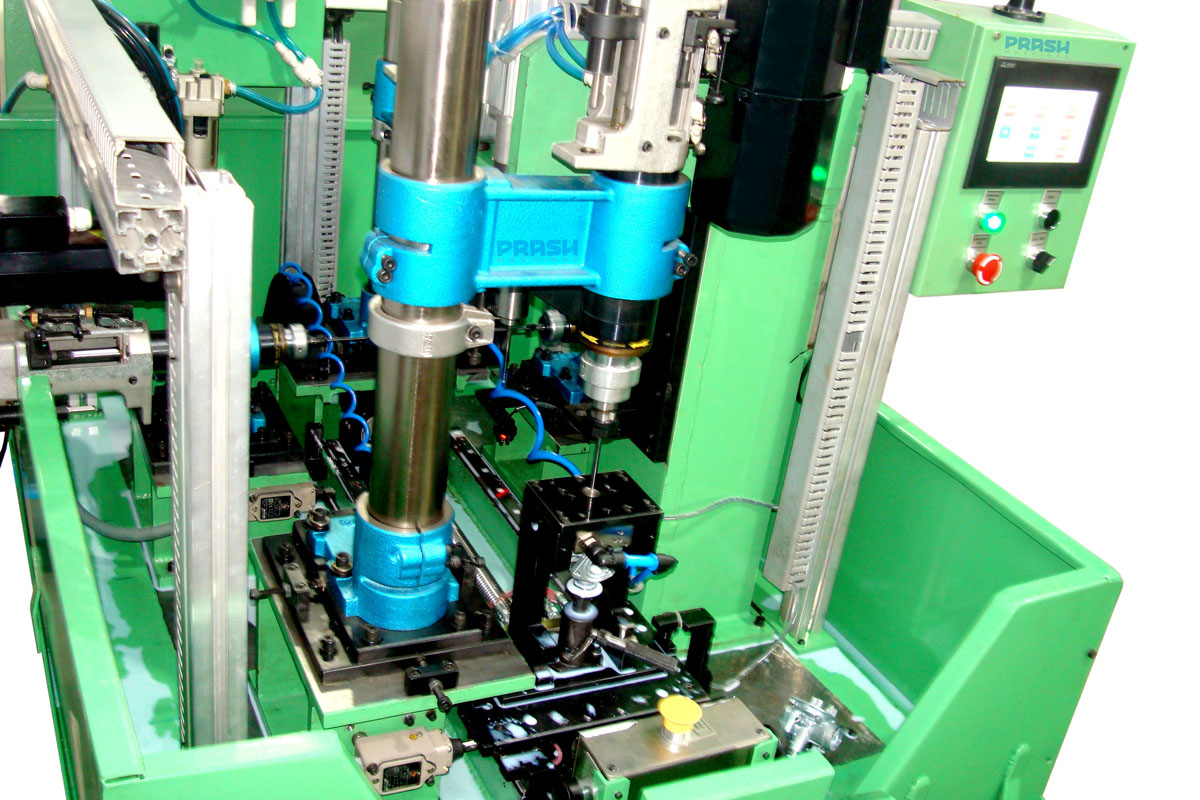

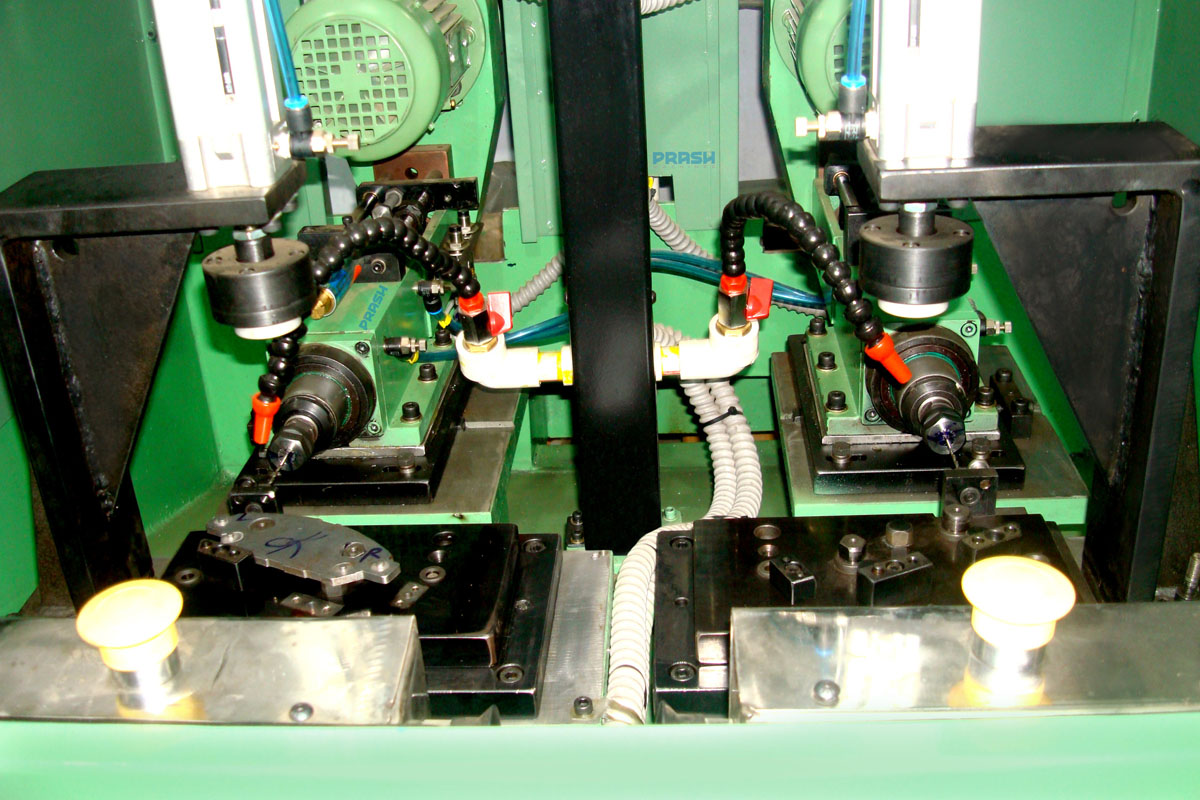

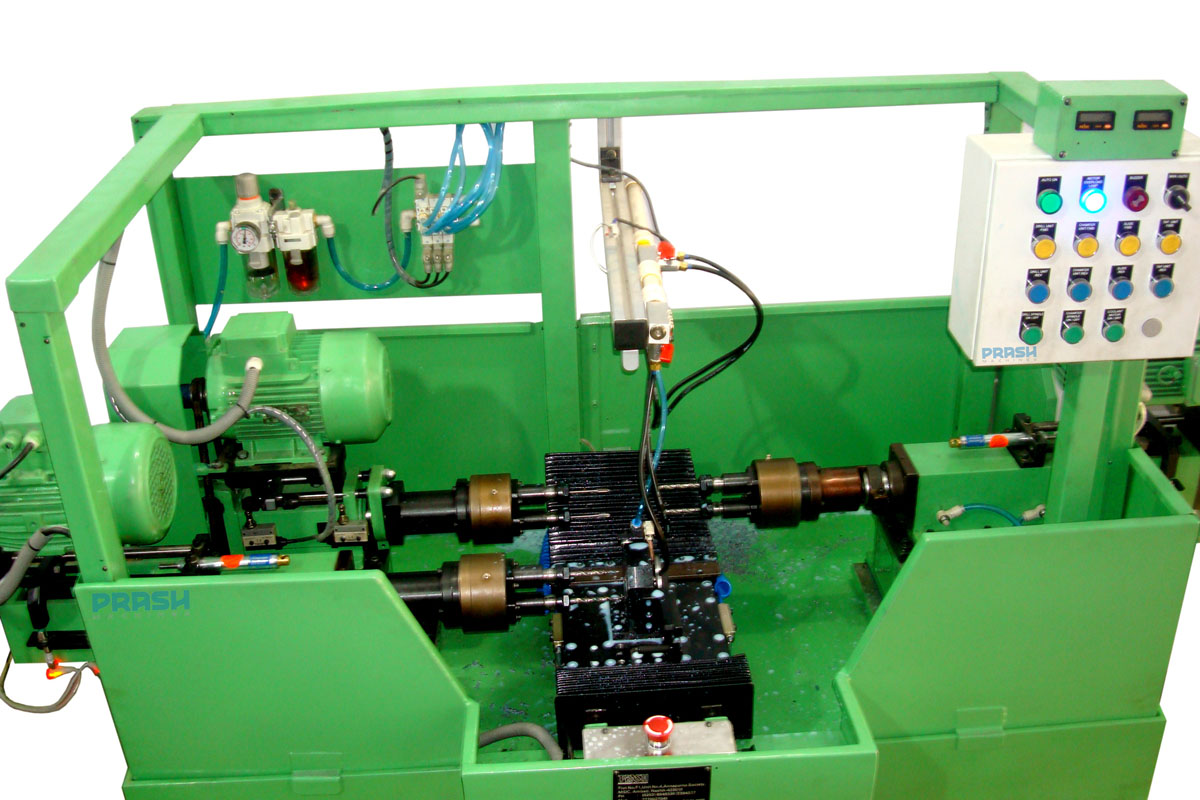

Multiple operation Drilling/Reaming

-

Servo Slider with LM Guide ways

-

Cam Type Manual Part Clamping

-

Auto recirculating coolant

-

Auto Lubrication

-

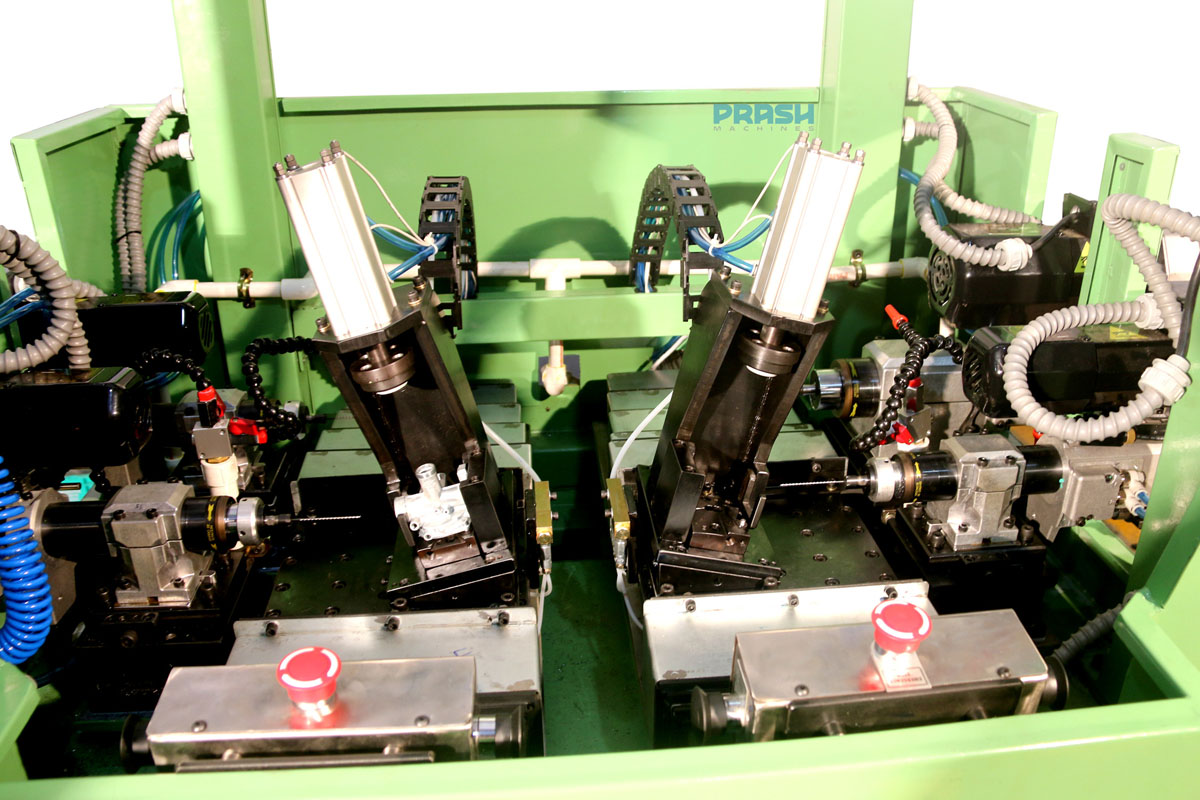

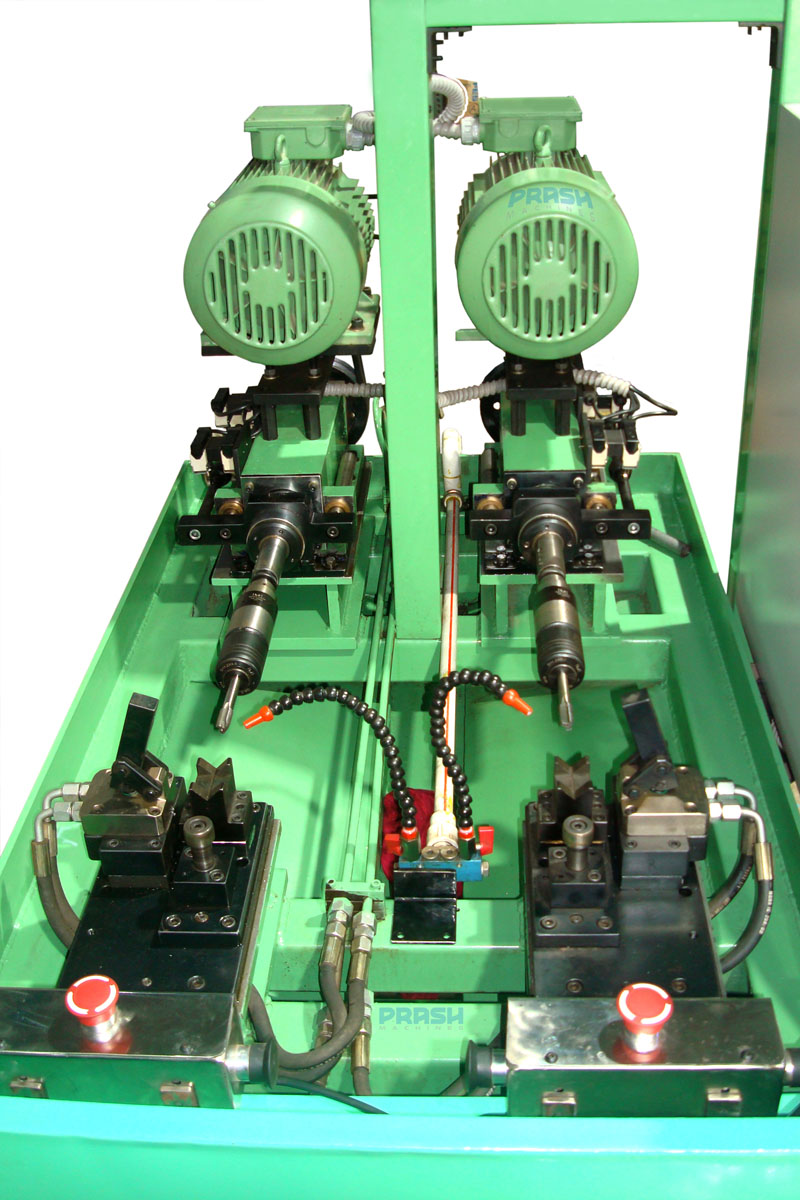

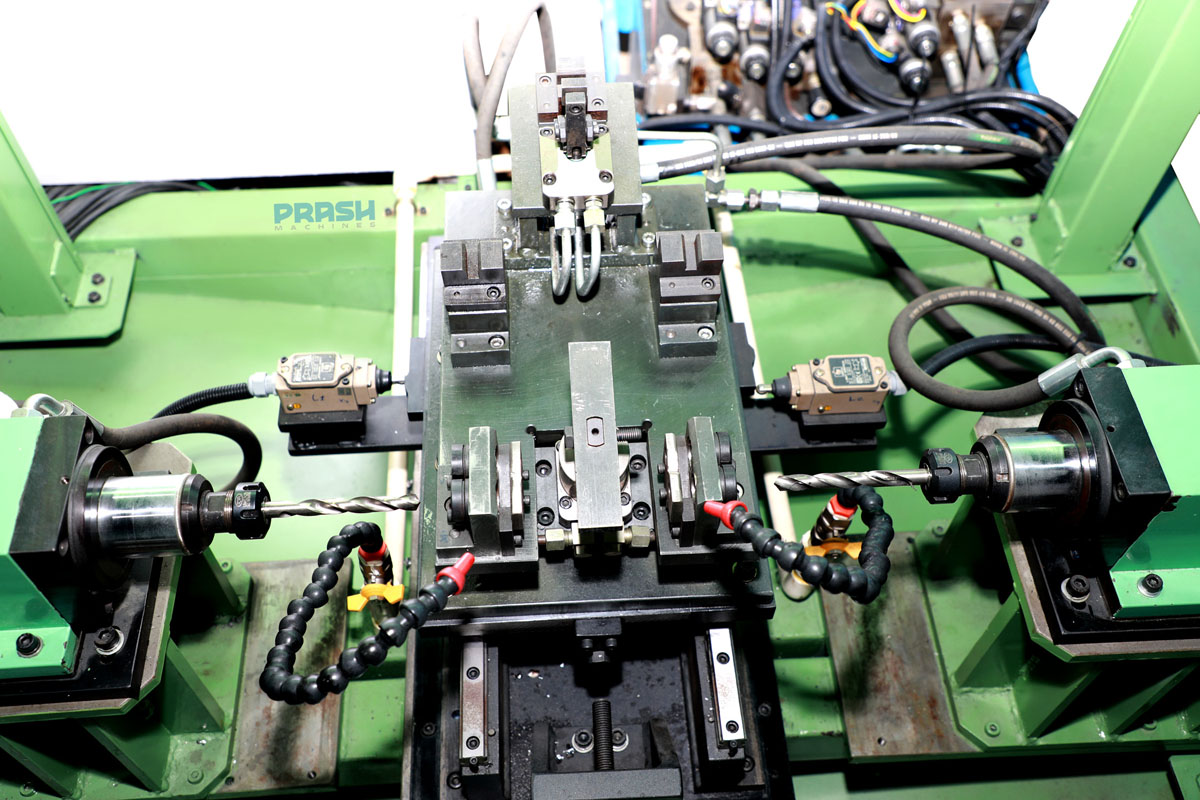

Multiple operation Drilling

-

Independent Stations for more productivity

-

Pneumatic Part Clamping

-

Auto recirculating coolant

-

Auto Lubrication

-

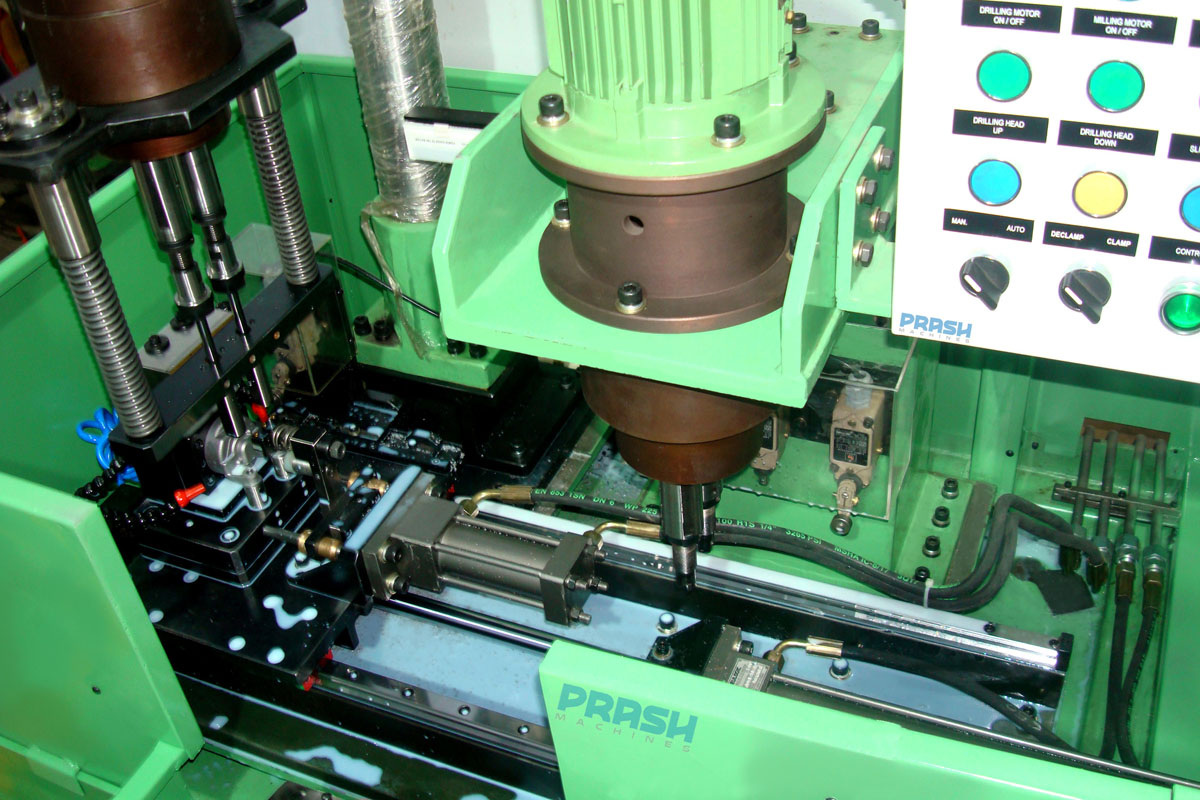

Milling/Boring/Reaming Heads

-

Hydraulic/Pneumatic/Servo Slide with Box Type Harden/LM Guide ways

-

Hydraulic/Pneumatic/Manual Part Clamping

-

Auto recirculating coolant

-

Auto Lubrication

-

Hydraulic/Pneumatic Drilling Heads

-

Rapid Forward-Feed-Rapid Return Stroke

-

Servo Slide for Peck Cycles & variables stokes

-

Different Speeds with Pulley ration/VFD

-

Multi Spindle Head mounting readiness

-

Rigid Plate/Pipe fabricated Stress relieved Table Structure

-

Auto recirculating coolant

-

PLC Control Panel with HMI

-

Quality Tap Cutting

-

Changeable Lead Screw &Nut for different pitch

-

Different Speed with Pulley ratio/VFD

-

Spindles with Length compensation & parallel Float

-

Multi Spindle Head mounting readiness

-

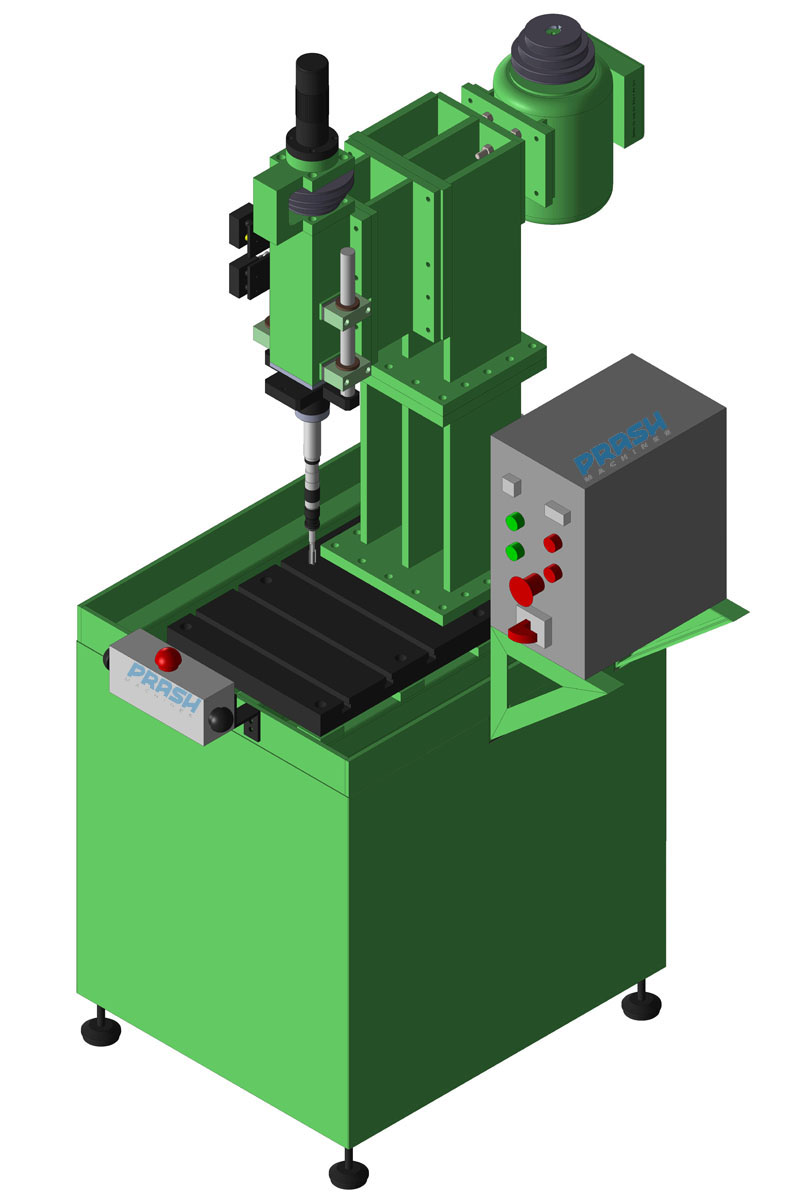

Brand : TCP

-

Model Name/Number : TCP-V1000 3 Axis

-

Drilling Capacity (Steel) : 55 mm

-

Spindle Speed Range : 1500 RPM

-

Overall Dimension (LxWxH) : 4000 mm X 3000 mm X 2800 mm

-

Width Of Base : 600 mm

-

Weight : 6000 Kg

-

Brand : TCP

-

Model Name/Number : TCP-V-500 3 Axis

-

Drilling Capacity (Steel) : 40 mm

-

Spindle Speed Range : 15000 RPM

-

Overall Dimension (LxWxH) : 2800 mm X 1900 mm X 2350 mm

-

Controller : Siemens

-

Width Of Base : 375 mm

-

Weightd : 2800 Kg

-

Spindle Main Motor : 20 HP

-

Minimum Order Quantity : 1 Unit

-

Country of Origin : Made in India

-

Material : Mild Steel

-

Usage/Application : PCD

-

Automation Grade : Automatic

-

Table Working Surface : 2200 x 1500 x 2300

-

Approx. Weight : 2000Kgs

-

Model Name/Number : TCP-V-500 (2 Axis)

-

Chuck Size : 300 x 4 Jaw Manual Chuck

-

Power : 10HP

-

Functions : Drilling

-

Layout : Vertical

-

Minimum Order Quantity : 1 Unit

-

Country of Origin : Made in India

-

Material : Mild Steel

-

Usage/Application : PCD

-

Automation Grade : Automatic

-

Table Working Surface : 2900 x 1950 x 2350

-

Approx. Weight : 3200 Kg

-

Model Name/Number : TCP-V-800 (2 Axis)

-

Chuck Size : 500 x 4 Jaw Manual Chuck

-

Power : 20HP

-

Functions : Drilling

-

Layout : Vertical

-

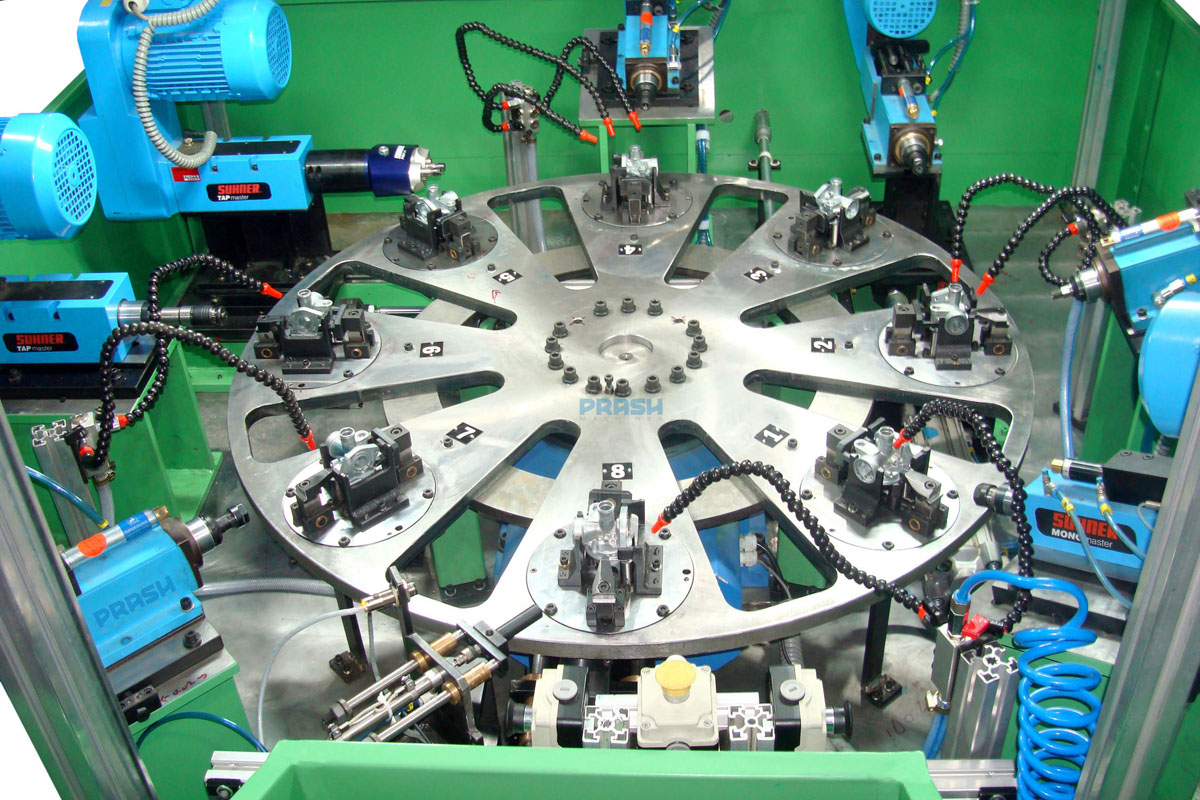

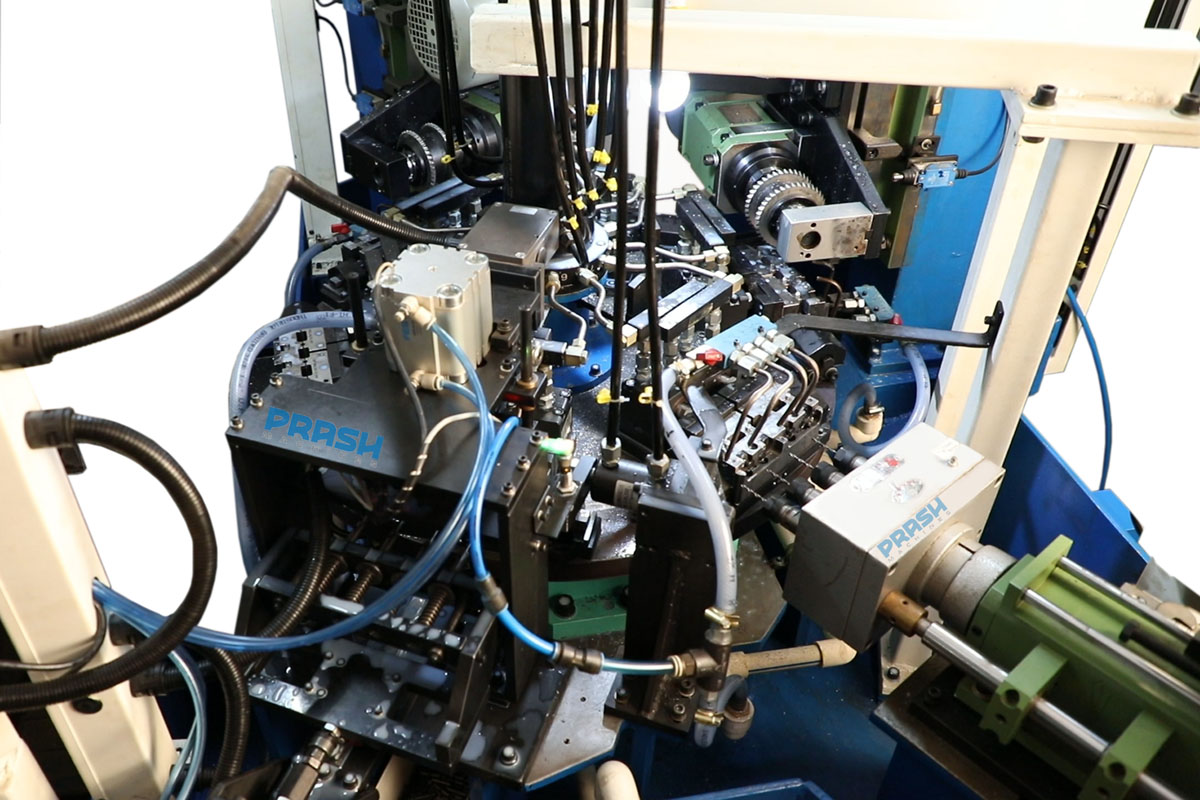

Multiple operation Drilling/Tapping/Reaming

-

Rotary Indexer with Hirth Coupling

-

Fixture Auto Indexing

-

Multi Spindle Drilling

-

Auto recirculating coolant

-

Multiple Operations Drilling/Reaming/Chamfering

-

Rotary Indexer with Hirth Coupling

-

Auto Fixture Indexing

-

Multi Spindle Drilling/Reaming

-

Multiple operation Drilling/Tapping/Milling

-

Multi Spindle Drilling/Tapping

-

Toggle Clamp Fixture

-

Auto recirculating coolant

-

Multi Station Tapping

-

Hydraulic Part Clamping

-

Auto recirculating coolant

-

Pitch Control Tapping

-

Multi Station Tapping

-

Multi Station Drilling

-

Auto recirculating coolant

-

Pneumatic Part Clamping

-

Pneumatic Drilling Head

-

Multiple Part Clamping Fixture

-

Pneumatic High Speed Drilling Heads

-

Pneumatic Slide/LM Guide Ways

-

Multi Spindle Drilling

-

Multi Spindle Milling

-

Linear Hydraulic Slide/ LM Guide Ways

-

Multi Spindle Milling

-

Linear Hydraulic Slide/ LM Guide Ways

-

Auto recirculating coolant

-

Hydraulic Part Clamping

-

Linear Hydraulic Slide

-

Hydraulic Part Clamping

-

Auto recirculating coolant

-

Multi Spindle Drilling/Chamfering/Tapping

-

Manual Clamping

-

Linear Pneumatic Slide/LM Guide Ways

-

Auto recirculating coolant

-

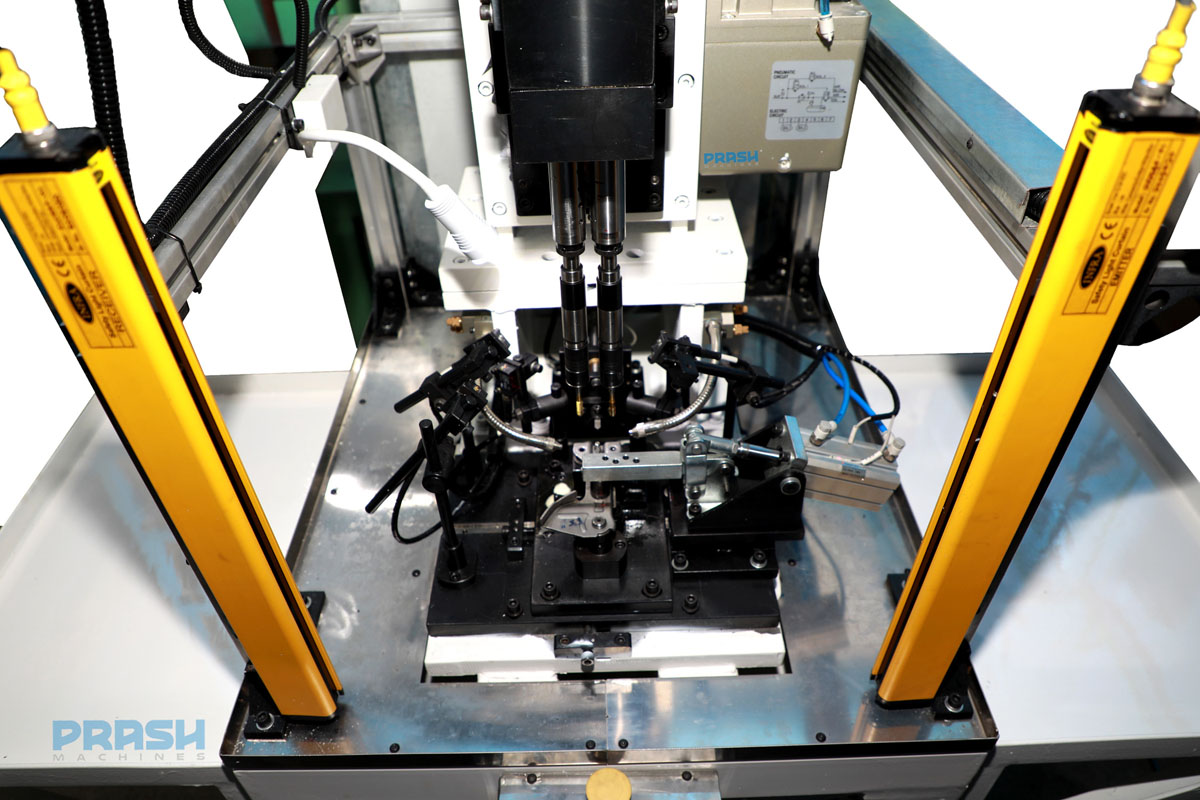

Multi Spindle Tapping

-

Pneumatic Part Clamping

-

LH/RH Part Variants Adjustment

-

Pneumatic Part Clamping

-

Tap Breakage Warning

-

Auto Tap Lubrication With Air Blow

-

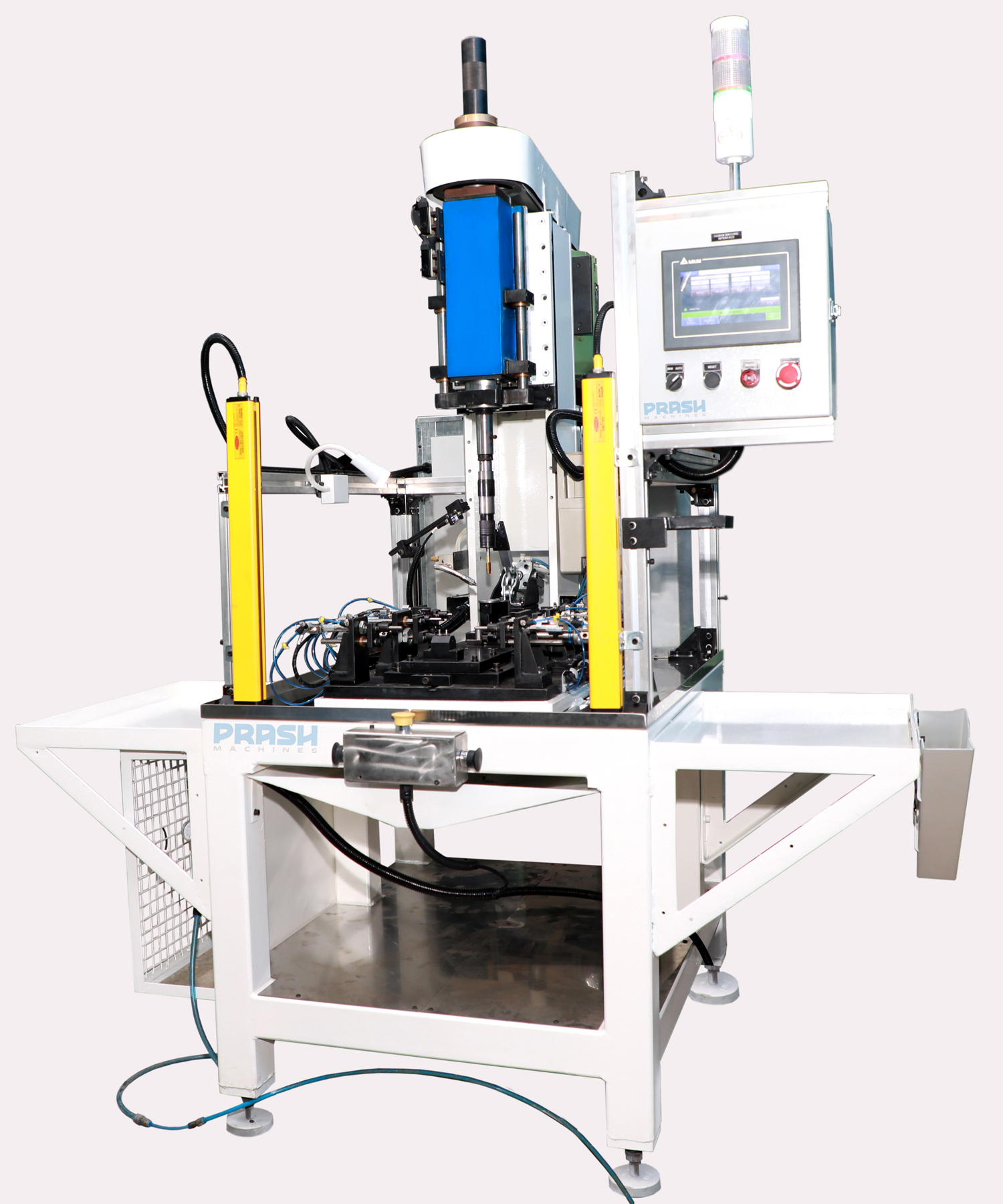

Pitch Control Tapping

-

Pneumatic Part Clamping

-

Tap Breakage Warning

-

Hole Confirmation Sensor

-

LH/RH Part Variants Adjustment

-

Auto Tap Lubrication With Air Blow

-

Safety Light Curtains

-

Safety Light Curtains

-

Multi Spindle Drilling

-

Quill Type Drilling Head

-

Hydraulic Part Clamping

-

Multi Spindle Drilling

-

Fixture Indexing

-

Quill Type Drilling Head

-

Auto recirculating coolant

-

Smooth & Crack Free Surface Finish

-

Long Tool Life

-

Stroke Adjustment

-

Compact Design

-

Multi Spindle Drilling

-

Multi Parts Grooving

-

Hole Confirmation Unit

-

Drill Breakage Indication

-

Hydraulic Part Clamping

-

Hydraulic Rotary Union

-

Auto Part Unloading

-

Auto recirculating coolant

-

Auto Fixture Cleaning

-

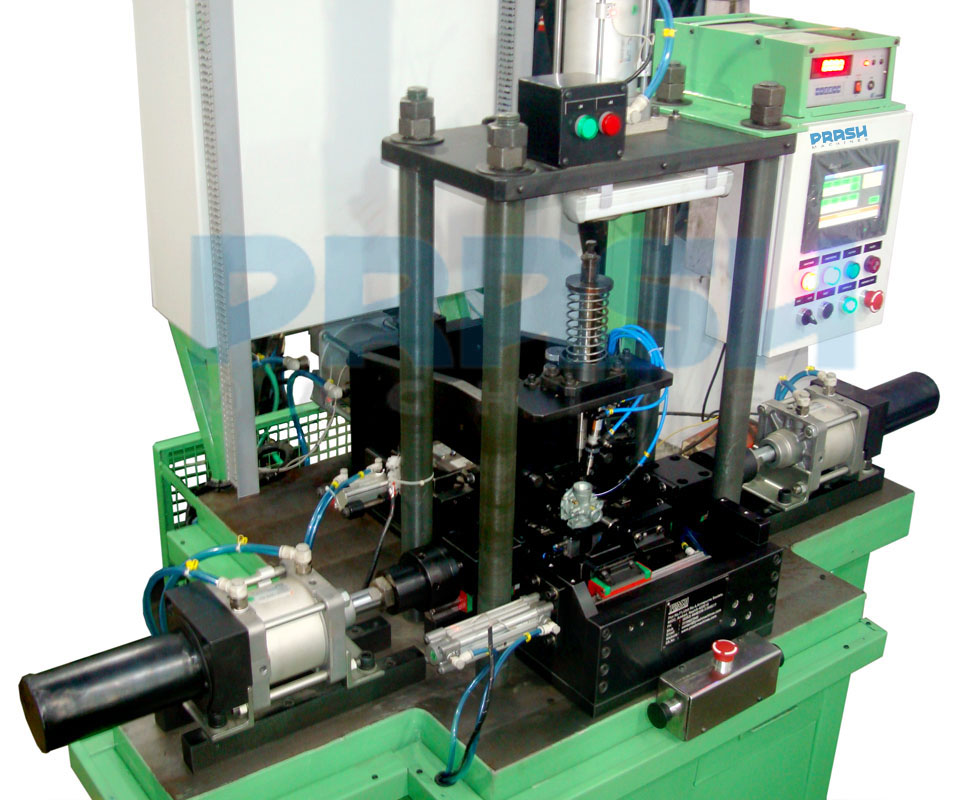

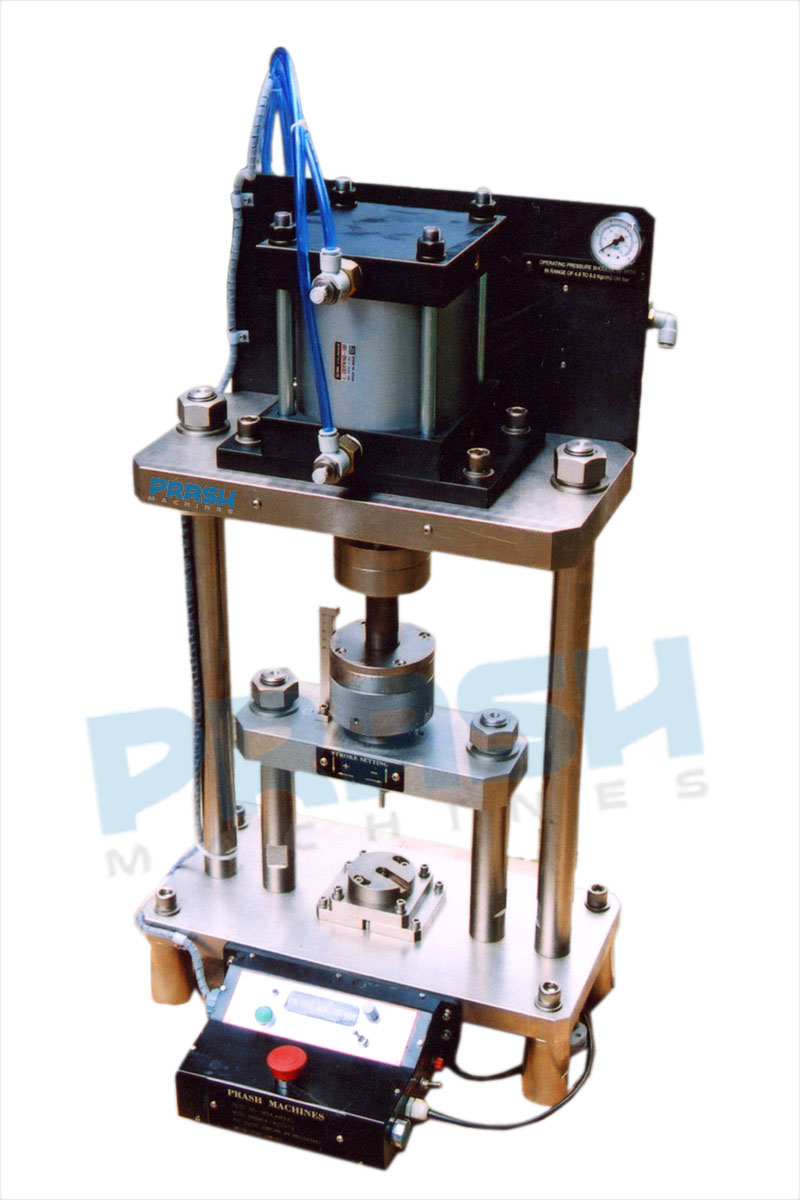

Capacity: 1 T

-

Construction: Four Pillar

-

Actuation: Pneumatic

-

Load Cell: 1 T

-

Stroke Control: Adjustable

-

Electrical Control: PLC

-

Safety: Two Hand Push Button

-

Capacity: 1 T

-

Construction: Four Pillar

-

Stroke Control: Adjustable

-

Load Cell: 1 T

-

Electrical Control: PLC

-

Safety: Two Hand Push Button

-

Capacity: 1 T

-

Construction: Four Pillar

-

Actuation: Pneumatic

-

Load Cell: 1 T

-

Stroke Control: Adjustable

-

Electrical Control: PLC

-

Safety: Two Hand Push Button

-

Capacity: 1 T

-

Construction: Two Pillar

-

Load Cell: 1 T

-

Stroke Control: Adjustable

-

Electrical Control: PLC

-

Safety: Electronic Safety Curtain with Two Hand Push Button

-

Capacity: 0.5T

-

Construction: ‘C’ Type

-

Stroke Control: Micromatic Adjustable

-

Electrical Control: Contactor Relay Logic

-

Safety: Two Hand Push Button

-

Capacity: 1T

-

Construction: Special

-

Load Cell: 1 T

-

Stroke Control: Micromatic Adjustable

-

Electrical Control: PLC

-

Safety: Two Hand Push Button

-

Capacity: 1T

-

Construction: Special

-

Load Cell: 1 T

-

Stroke Control: Programmable

-

Electrical Control: PLC

-

Safety: Sliding Close Cabinet

-

Capacity: 1T

-

Construction: Two Pillar

-

Stroke Control: Micromatic Adjustable

-

Electrical Control: Contactor Relay Logic

-

Safety: Two Hand Push Button

-

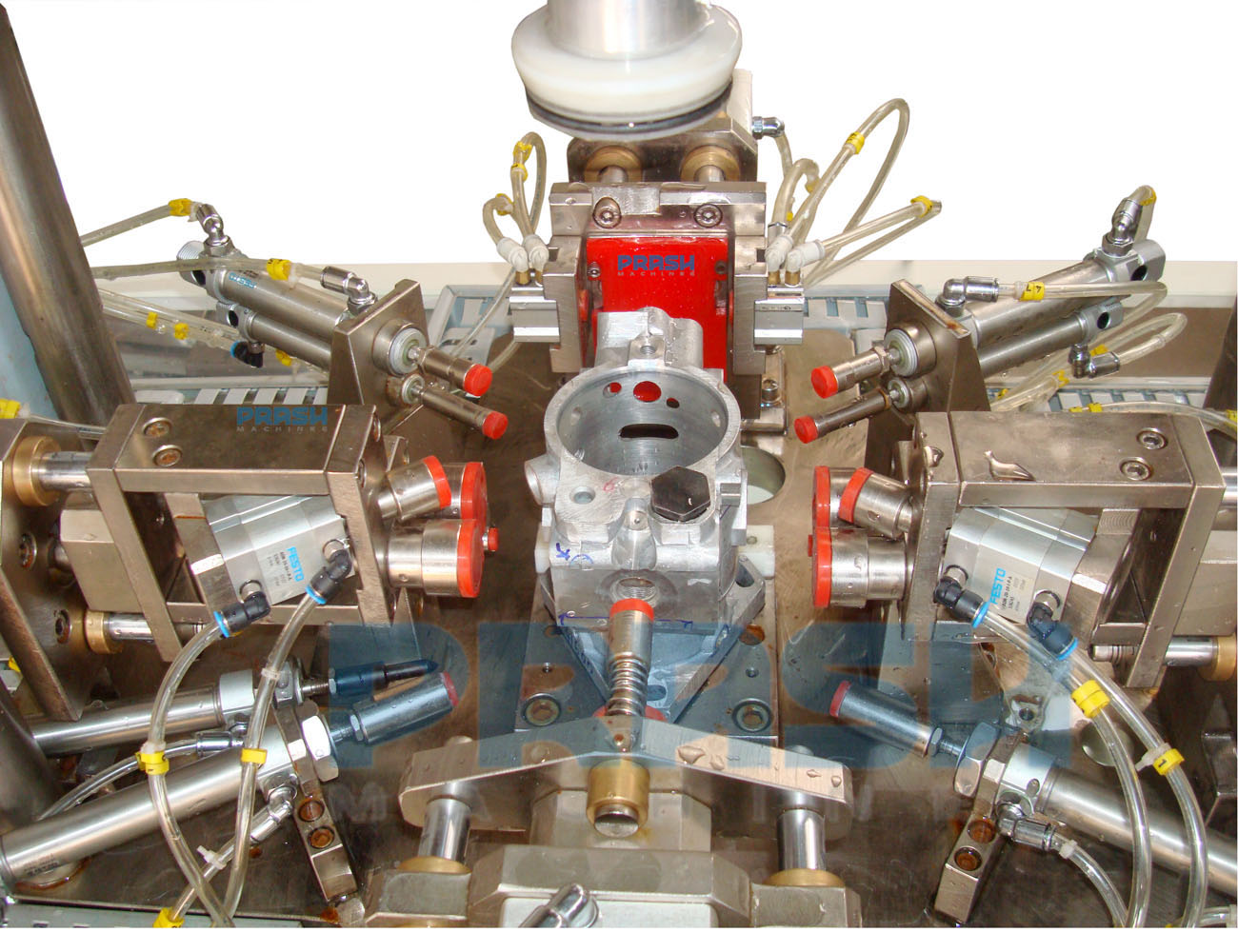

Test Pressure: 1.5 bar

-

Leak Rate: 30 Pascal per 4 seconds

-

Cycle Time: 9 seconds

-

Medium: Air

-

Automation: Auto clamping, Sealing and Punch mark

-

Seals: Silicon

-

Connectors: Ferrule type leak proof

-

Electrical Control: PLC

-

Test Pressure: 2 bar

-

Cycle Time: 15 Seconds

-

Medium: Air

-

Clamping: Manual by Toggle Clamp

-

Seals: Silicon

-

Connectors: Ferrule type leak proof

-

Test Pressure: 2 bar

-

Cycle Time: 15 Seconds

-

Medium: Air/ Helium

-

Clamping: Pneumatic Auto

-

Seals: Silicon

-

Connectors: Ferrule type leak proof

-

Test Pressure: 1.5 bar

-

Leak Rate: 30 Pascal per 4 seconds

-

Cycle Time: 9 seconds

-

Medium: Air

-

Automation: Auto clamping, Sealing and Punch mark

-

Seals: Silicon

-

Connectors: Ferrule type leak proof

-

Electrical Control: PLC

-

Test Pressure: 1.5 bar

-

Leak Rate: 30 Pascal per 4 seconds

-

Cycle Time: 9 seconds

-

Medium: Air

-

Automation: Auto clamping, Sealing and Punch mark

-

Seals: Silicon

-

Connectors: Ferrule type leak proof

-

Electrical Control: PLC

-

Test Pressure: 1.0 bar

-

Measurement: By Electronic Pressure Transducer

-

Cycle Time: 12 seconds per two parts

-

Medium: Air

-

Automation: Auto Loading, Testing and Segregation

-

Seals: Silicon

-

Connectors: Ferrule type leak proof

-

Electrical Control: PLC

A PHP Error was encountered

Severity: Notice

Message: Undefined offset: 0

Filename: views/product_view.php

Line Number: 82

A PHP Error was encountered

Severity: Notice

Message: Trying to get property 'in_id' of non-object

Filename: views/product_view.php

Line Number: 82

A PHP Error was encountered

Severity: Notice

Message: Undefined offset: 0

Filename: views/product_view.php

Line Number: 115

A PHP Error was encountered

Severity: Notice

Message: Trying to get property 'st_video' of non-object

Filename: views/product_view.php

Line Number: 115